Origin and risks

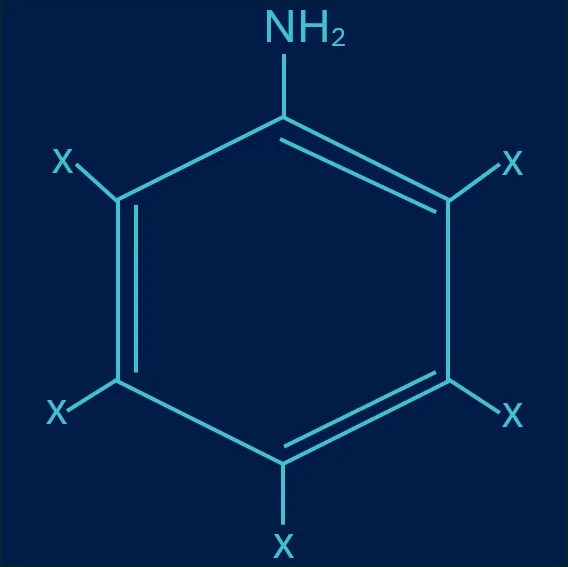

Primary aromatic amines often occur as impurities or degradation products in dyes (e.g. azo pigments). They can also be formed by hydrolysis from isocyanates in polyurethane adhesives or other PU systems. Some PAAs are considered carcinogenic or mutagenic, which is why their migration into food is problematic.

Measurement / Analysis

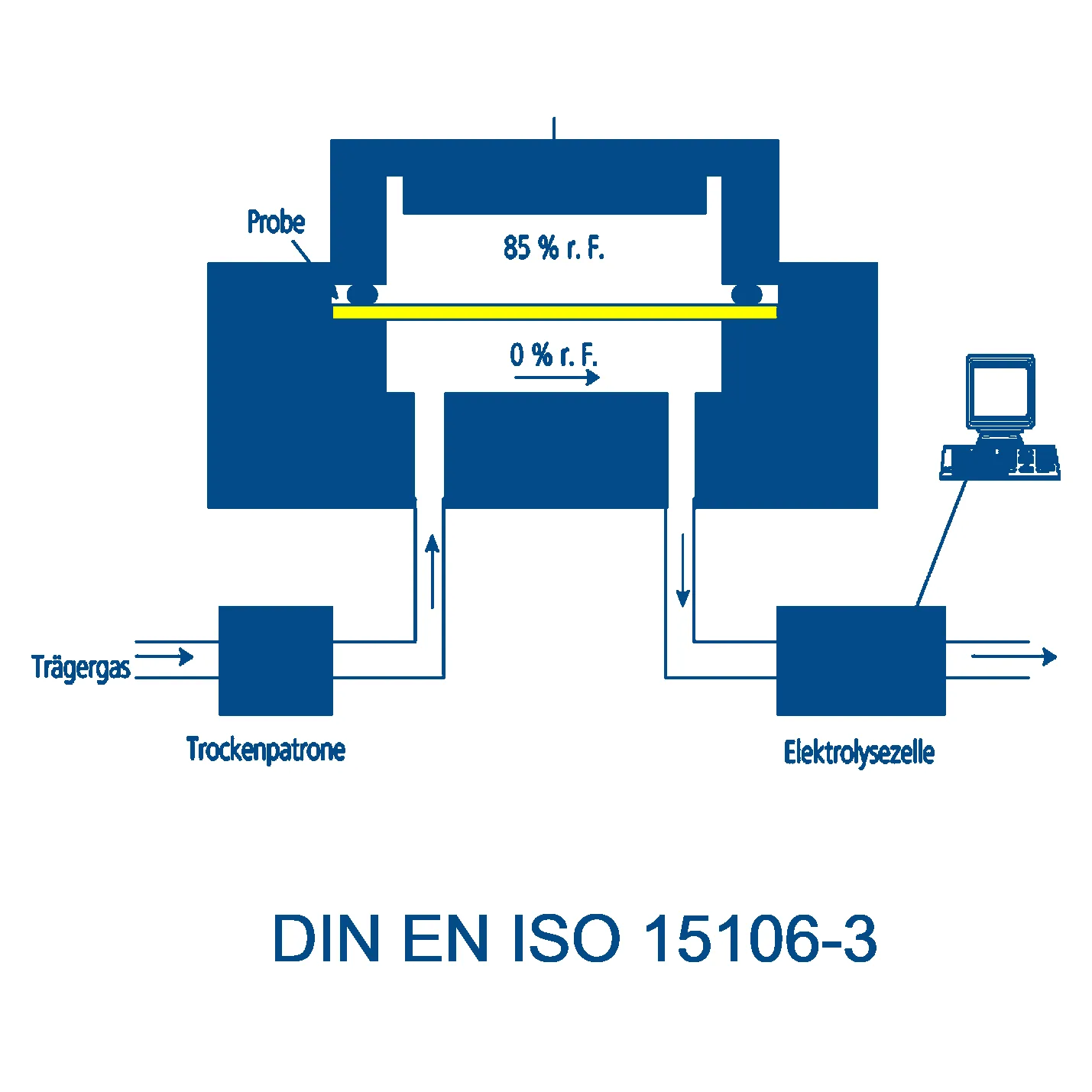

3% acetic acid or water is often used as a simulant for migration testing. Recent studies show that some paA are unstable in acetic acid under standard conditions, while they remain more stable in water. However, the influence of the simulant on protonation (relevant, for example, in paA from laminating adhesives) has often not yet been sufficiently researched.

Liquid chromatography is usually used to analyse the migrants:

- High-performance liquid chromatography with diode array detector (HPLC-DAD)

- High-performance liquid chromatography coupled with tandem mass spectrometry (HPLC-MS/MS)

The photometric summation method (Section 64 LFGB, method L 00.00-6) is still used in some areas of industry, but it can only be used to provide a rough estimate of compliance with the sum limit of 0.01 mg/kg and is not suitable for conformity testing because it does not provide sufficient recovery for all possible amines.

Regulatory requirements and assessments

Various regulations (e.g. Plastics Regulation, Commodities Regulation and BfR recommendations) contain similar provisions:

- Primary aromatic amines that are considered carcinogenic (CLP category 1A/1B) must be undetectable if no specific migration limit (SML) exists.

- According to Article 11(4) of the Plastics Regulation (EU) No 10/2011, a detection limit of 0.002 mg/kg per individual substance applies to such paA.

- The sum of unlisted and non-carcinogenic paA must not exceed 0.01 mg/kg.

The BfR recommends applying the ALARA principle (As Low As Reasonably Achievable).

Planned adjustment & discussion

The minutes of the 34th meeting of the BfR Commission for Commodities document that the BfR plans to include a new footnote in its recommendations: For carcinogenic paA, a transition above 0.15 µg/kg food should not be detectable. At the same time, the maximum permissible detection limit is to remain at 2 µg/kg food.

It follows that measured values above 0.15 µg/kg would be considered unacceptable/non-compliant.

The reason given is that some laboratories can achieve detection limits lower than the current detection limit of 2 ppb. The handling of measurement uncertainty, analytical implementations and, if necessary, gradual approximations to the target value of 0.15 µg/kg food must be examined and implemented in detailed concepts.

If you have any questions, please contact fcm@innoform.de. We will be happy to provide you with a quote for the determination of primary aromatic amines.

You can find examinations on paA here.

An article by Heike Schwertke