Practical testing of water vapour permeability – which method makes sense when

The Water / Moisture Vapour Transmission Rate (WVTR) is a key parameter for the durability, functionality and sustainability of flexible packaging. Innoform Testservice offers three recognised laboratory methods that together cover the entire practical range from breathable bags to high-barrier films. Below you can find out which test principle has proven itself in which application scenarios.

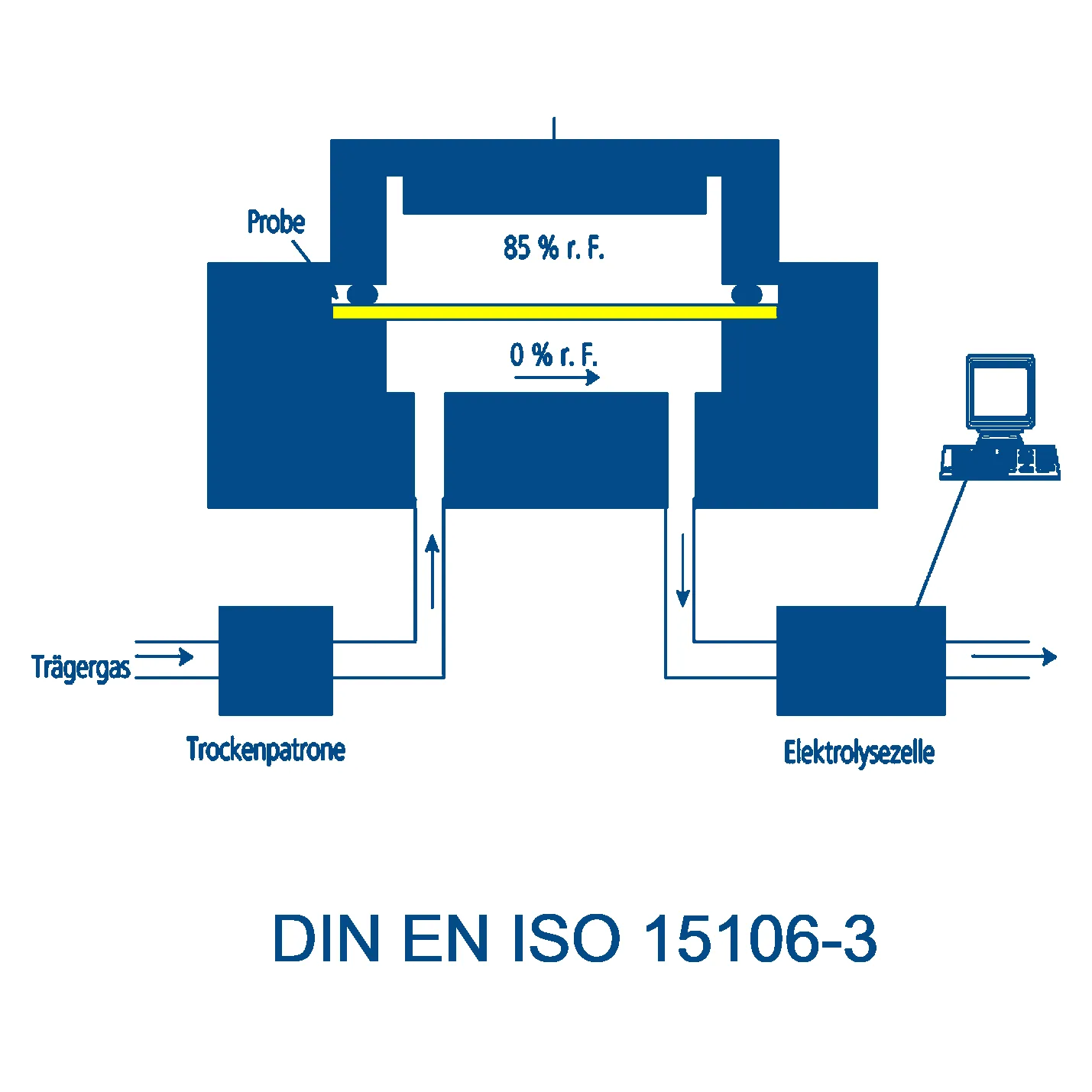

1 Electrolytic / hydrolysis sensor (ISO 15106-3)

Standards: DIN EN ISO 15106-3

Area of application:

- High-barrier films, metallised or inorganically coated structures

- WVTR from 0.01 g – m-² – d-¹ to approx. 100 g – m-² – d-¹

- Moulded packaging (pouches, bottles, pharmaceutical primary packaging)

Why choose?

The phosphorus pentoxide (or calcium chloride) sensor system decomposes incoming water vapour electrolytically; the required current is directly proportional to the permeate. As a result, the method achieves very low detection limits and is suitable for premium barrier and shelf-life studies. Innoform offers the same technology for both flat films and complete packaging chambers.

2 Modulated infrared sensor (ASTM F 1249 / ISO 15106-2)

Normen: ASTM F 1249, DIN EN ISO 15106-2

Einsatzbereich:

- Typical packaging barriers (≈ 0.05 – 50 g – m-² – d-¹)

- Fast incoming goods and process control (results ≤ 2 h)

- Temperature and RH-controlled tests for validation studies

Why choose?

A modulated infrared detector measures the water vapour absorption in the carrier gas behind the sample. The method delivers reproducible results with short analysis times and automatic climate control – ideal for series testing and comparative material benchmarking.

3 Gravimetric cup method

Standards: DIN 53122-1, DIN EN ISO 12572, ASTM E 96

Area of application:

- Medium to high WVTR values (≈ 1 – 1000 g – m-² – d-¹)

- Straight, flat samples ≥ 50 cm²

- Quality control for standard laminates, paper/plastic composites, breathable construction films

Why choose?

The cup method is robust, inexpensive and widely recognised in standards. It measures the actual mass loss and is therefore ideal as a reference or for comparative measurements between laboratories. The disadvantages are longer measurement times (hours to days) and limited sensitivity for high-quality barrier films.

4 Decision-making aid at a glance

| Requirement | Typical WVTR | Sample | Recommended Innoform method | Comment |

|---|---|---|---|---|

| Budget-friendly reference, standard-compliant | > 0,5 g · m⁻² · d⁻¹ | ≥ DIN A5 film | Cup gravimetric | slow, very robust |

| Fast QC measurement in production | 0,05 – 50 | Foil or flat moulded part | IR sensor | Resultate ≤ 2 h |

| High barrier, food/pharmaceuticals | 0,01 – 0,05 | Foil or pack | Electrolytic | Highest sensitivity |

5 Practical recommendations

- Sample conditioning – at least 24 h under test climate to harmonise moisture gradients.

- Double measurement – Innoform carries out two determinations as standard in order to recognise outliers at an early stage.

- Order reference foils at the same time – have a known barrier tested once a year; this way you can keep an eye on the calibration in the long term.

- Select test climate – typically 23 °C / 85 % rH for food packaging, 38 °C / 90 % rH for tropical simulation.

Complete table of WVTR test methods for films & packaging

| Test method | Important standards | Typical WVTR range (g – m-² – d-¹) | Special features | Innoform for Flexpack usual |

|---|---|---|---|---|

| Gravimetric (cup: dry / wet) | DIN 53122-1, ASTM E 96, ISO 12572 | 0,5 – 1000 | favourable, reference | ✔ |

| Capacitive humidity sensor | ISO 15106-1 | 0,05 – 1000 | fast QC, medium sensitivity | ✖ |

| Modulated IR sensor | ASTM F 1249, ISO 15106-2 | 0,02 – 100 | automated, ±2 h Result | ✔ |

| Electrolytic / hydrolysis sensor | ISO 15106-3, ASTM F 2622 | 0,005 – 0,05 | High barrier, moulded packs | ✔ |

| Calcium corrosion test | (R&D, DIN SPEC in progress)- (R&D, DIN SPEC in progress) | 10⁻⁴ – 10⁻⁶ | Ultra-OLED barriers | ✖ |

| Optical-electrical hybrid calcium | – | < 10⁻⁶ | Combined measurement for photovoltaics | ✖ |

Summary

Whether standard laminate or high-tech barrier layer: Innoform’s gravimetric, IR and electrolytic processes cover practically every WVTR window of practical relevance. The choice depends on your target WVTR, the time window and the sample geometry – and ultimately determines how reliable your shelf life and process data are.

You can find the Innoform tests and contact persons here: