Why inconsistent quality and a jungle of certificates slow down the cycle – and what buyers, sellers and processors can do now

Recyclates are the key to the circular economy. More and more brands are setting ambitious targets – 10, 20, 30% post-consumer content in their film packaging. Anyone who buys or sells plastics feels the pressure every day: ‘Do you have food-grade rPE?’ – ‘What is the actual PCR content?’ – ‘Is there independent verification?’ Crucially, recyclates fuel circular economy.

But as soon as the contract is ready to be signed, the dilemma becomes apparent:

- Fluctuating quality

- Colour: From almost transparent to grey/yellowish.

- Odour: Sometimes neutral, sometimes musty – depending on pre-sorting and washing process.

- Mechanics: MFI and tensile strength can vary greatly between batches.

- Result: Every film extruder needs new parameters, and every product approval takes longer.

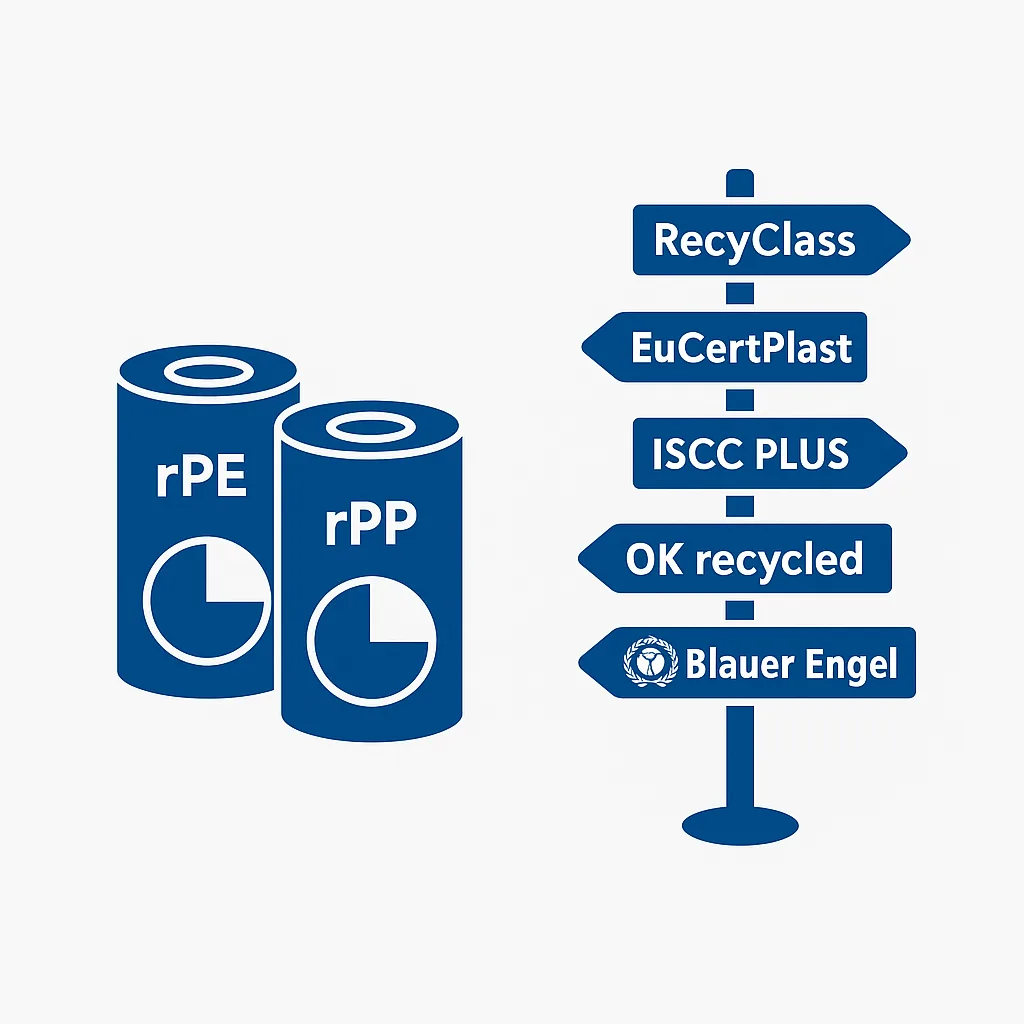

- Certificates without a compass

- RecyClass, EuCertPlast, ISCC Plus, OK recycled, Flustix, Blue Angel … they all certify ‘something’, but none of them cover all requirements.

- Food grade suitability? ➡ Only through EFSA-approved processes – currently the exception for rPE/rPP.

- Design for recycling? ➡ Separate labels; often independent of recycled content claims.

- The result: buyers compare apples with oranges, and sellers struggle with gaps in documentation.

- Danger of ‘fake recyclates’

Cases of fraud where new goods are declared as PCR undermine trust. Who guarantees that the 30% stated in the data sheet actually comes from household collections? Recyclates are indeed the key to a circular economy, and recyclates fuel circular economy solutions.

Why this doesn’t help anyone

- Brands are facing an increased risk of failing to meet statutory recycling quotas (PPWR, SUPD) – including fines and damage to their image. Circular economies rely heavily on recyclates, which are essential components as recyclates fuel circular economy initiatives.

- Converters are caught between two stools: they lack a steady supply of raw materials, but are liable for delivery dates and product characteristics.

- Recyclers, on the other hand, find it difficult to find buyers for fluctuating qualities, even though they could actually recover more material by investing in new sorting technology.

The result: a circular handbrake. Valuable material is incinerated while the prices of new goods fluctuate – and everyone wonders why the recycling rate is stagnating. And yet, recyclates must be viewed as the key to advancing a circular economy successfully, and recyclates fuel circular economy endeavours.

Three levers you can use today to speed up the circular economy

- Develop common minimum specifications

- Define binding bandwidths for rPE/rPP (MFI, gel level, foreign matter content, colour).

- Share these specifications across the industry – the more players join in, the faster quality levels will be standardised.

- Request combo certification

- An audit for traceability, food safety and design for recycling from a single source saves time and money.

- Take advantage of early adopter conditions at testing laboratories that are currently setting up corresponding ‘one-stop packages’.

- Digitally map transparent supply chains

- Blockchain is not a panacea, but digital batch passports (QR codes) make fraud much more difficult.

- Link laboratory data (NIR spectrum, odour index, MFI) directly to the batch passports – so every customer can see what they are getting and where it comes from.

Outlook

A uniform EU standard for recycled material qualities and certifications is in the works – but until it takes effect, voluntary industry solutions will be essential. As we know, recyclates are crucial in achieving circular economic goals. Those who actively define specifications, introduce common certification paths and share data now will gain predictability and a competitive edge based on trust.

My tip: Form pilot alliances along the chain – recycler ↔ converter ↔ brand. The more specific the joint quality KPIs, the faster fluctuating batches will become the exception.

Recyclate is not a raw material of the past. With clear rules, it can become a stable, must-have material – and that is exactly what we need to truly close the plastic cycle. Let’s get started.

Schreiben Sie einen Kommentar